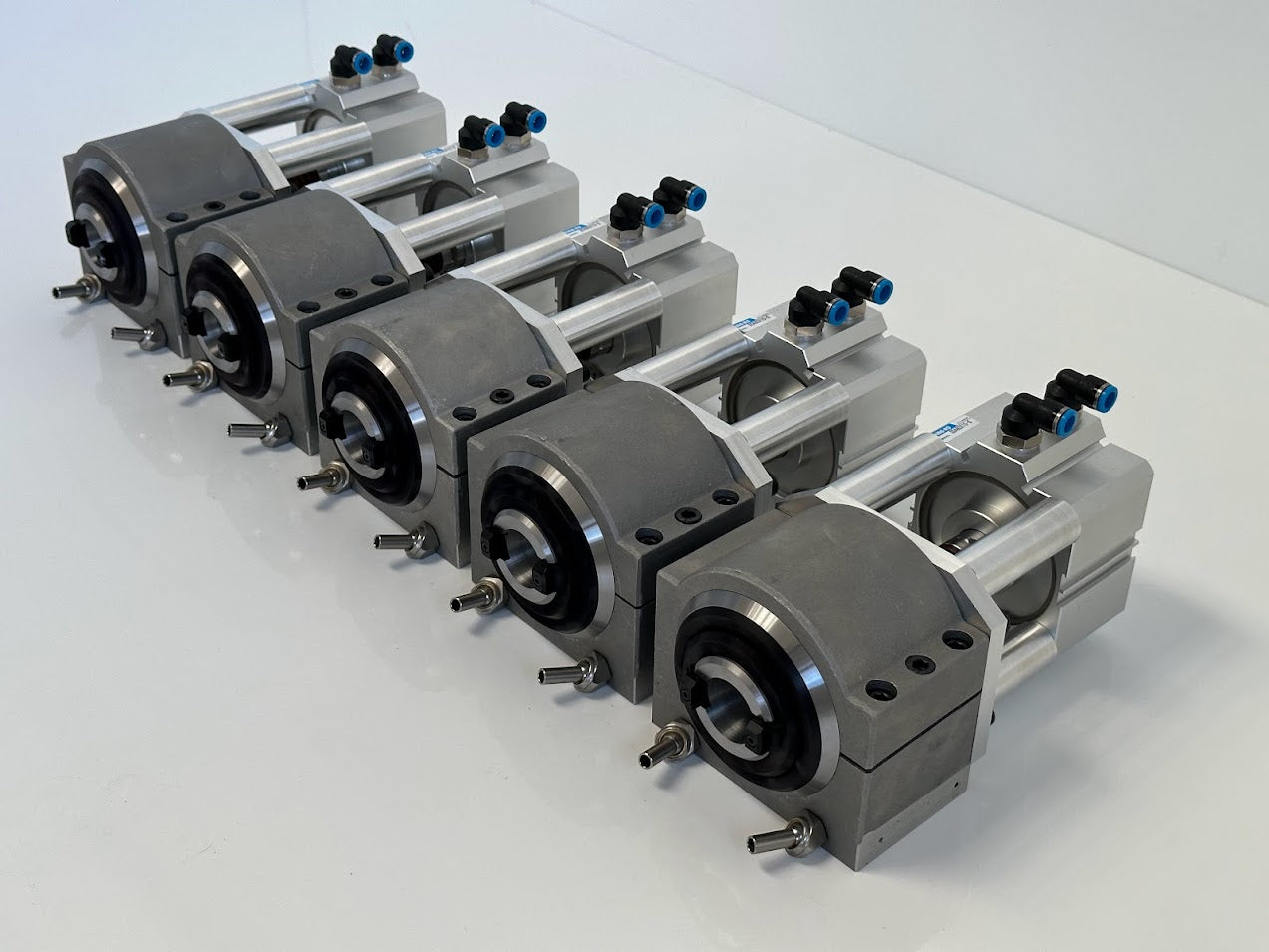

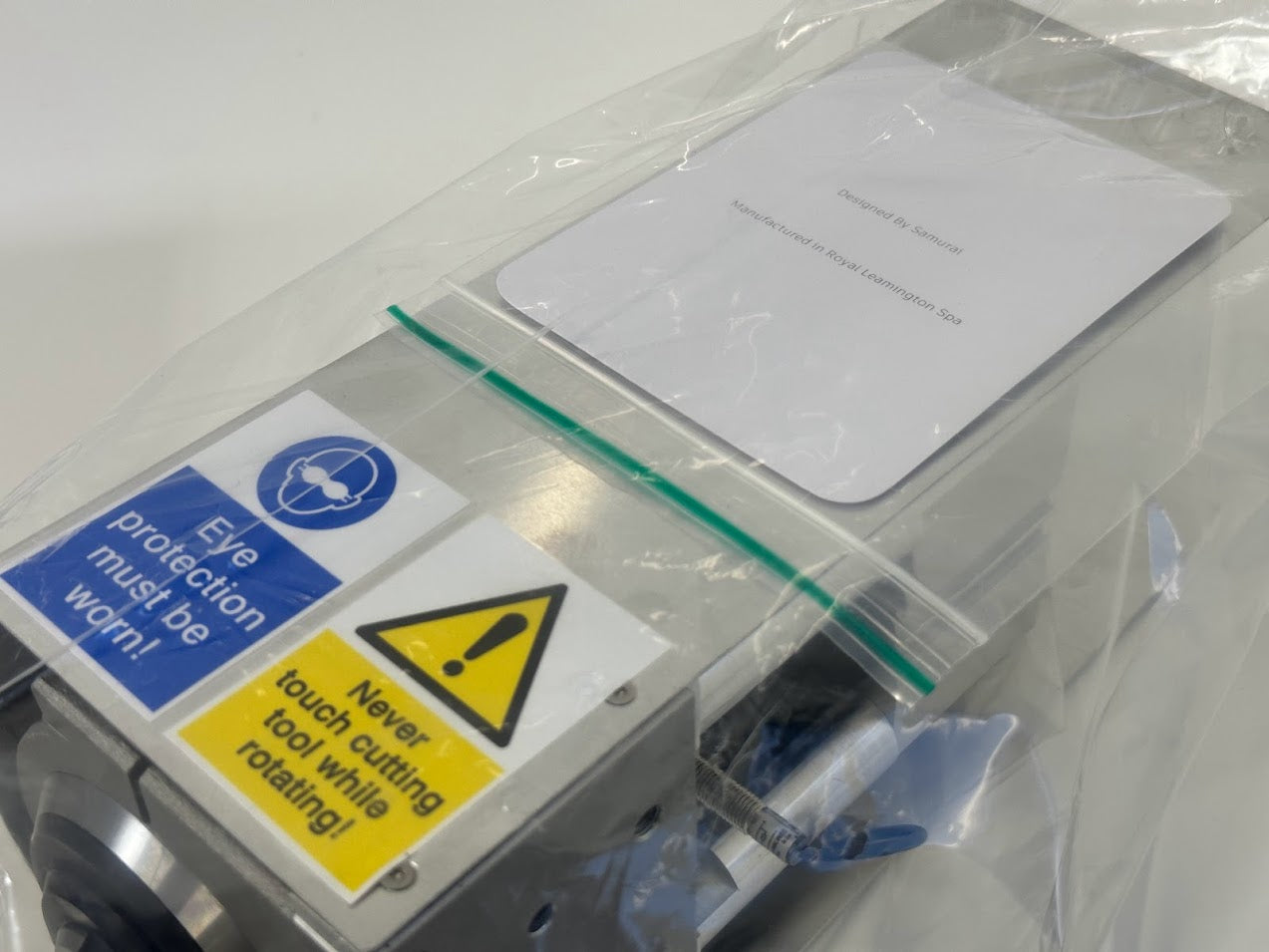

Samurai 120H BT30 Spindle 8K RPM (Final batch)

Samurai 120H BT30 Spindle 8K RPM (Final batch)

Couldn't load pickup availability

For a while the options for BT30 spindles have been very limited, leaving you to decide between a very high end (and large) spindle costing thousands, or a spindle from China which is affordable but too large for a lot of small DIY CNC machines.

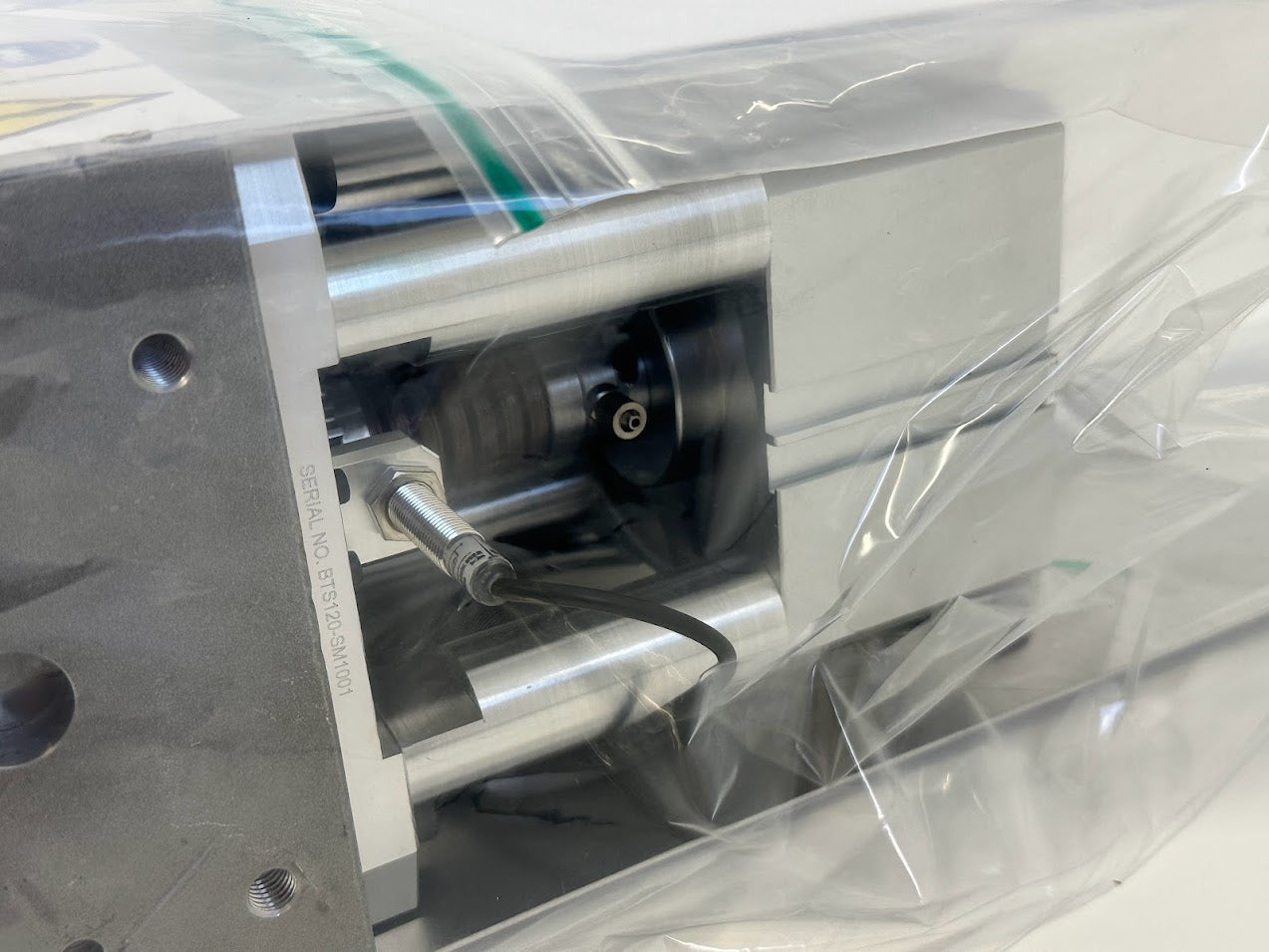

Samurai Machine tools have created a spindle to fill that gap between an ATC spindle and an ER collet or R8 spindle. It is a BT30, ATC ready spindle but the height is only 220mm (8 inch) which means small machines can finally have a BT30 ATC system capable of cutting steel, and at a low cost.

Benefits of BT30 over R8 or similar:

- Reduced Runout

- Increased Rigidity

- Fewer parts between the spindle and the tool

- No tool slippage

- No tool pull-out

- Low cost tool holders available

- Huge variety of toolholders (e.g. Hydraulic chuck or heat shrink tooling)

- ATC capable

- High torque capability

- Larger diameter tooling

- Tool changes in under 2 seconds are possible

Technical Details

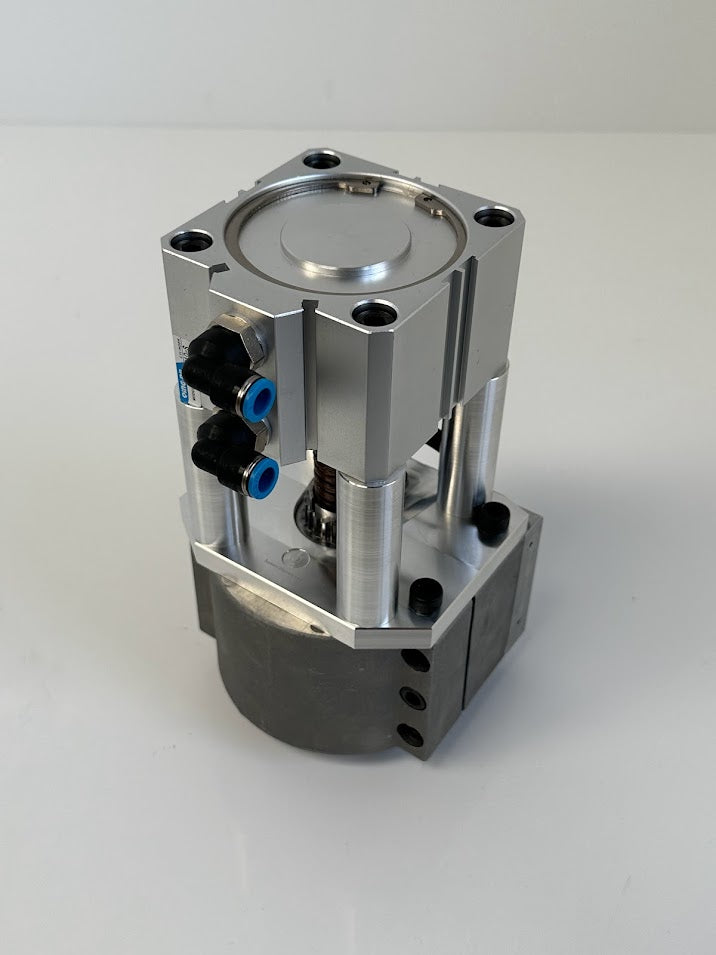

ATC Air purge

If you would like to use an Automatic Tool Changer this feature is a must have. When changing tools there could be chips (swarf) on the toolholder that has come from machining operations and if those chips aren't removed before changing tools, the BT30 taper will be damaged and if you continue machining, the parts you make may be out of tolerance and have a poor surface finish.

Through spindle air

This machine features 3 bar periodic* through spindle air, allowing you to blast chips out of deep pockets when milling or drilling.

*TSA must not be used continuously, only in short bursts.

8000 RPM

Unlike many spindles you may have seen, this is not a router spindle. It is designed to run on machining centers capable of holding large tools and taking bigger cuts, which requires lower rpm and more torque. While the spindle bearings are rated for 8000 RPM it will need active cooling to run higher rpm's continuously. General cutting should not use more than 6000 to preserve bearing life.

A fan should be placed above the cylinder and point down at a 45° angle to cover the spindle motor and the spindle. The spindle should also be mounted to an aluminum block to help take away some heat and ideally this block would be water cooled.

Note: New spindles may generate more heat as they require a run in period, this can take up to 4 weeks depending on use.

Eliminating runout

With this spindle it is possible to achieve under 5 micron runout by using a 'tapping' method. See this video by NYC CNC.

- Samurai 120 BT30 ATC Spindle

- 6mm Alignment dowel pins

- 4x M3 Spindle cover mounting screws

- Aluminum Spindle cover

- Setup support

- Spare bolts / washers

- (toolholder or end mill shown in images not included)

Accessories:

- 1/4" BSP Oil, Water Separator / Air Filter, regulator

- 2 Position 5 Way AIRTAC Air Solenoid Valve 4V110-06 1/8"BSPT

- 8mm Nylon Pneumatic Right Angle 90° MALE STUD push-fit

- 8mm 2m SMC Pneumatic tubing (clear blue)

Setup Support

Correct Use of Product

It is very important that this spindle is setup and used correctly otherwise it may cause damage or harm. There are many factors involved in getting this spindle to perform to an acceptable standard for a machine tool but here is a list of the basic things that need to be considered for safety / durability reasons:

- Correct spindle motor, pulley and belt to not exceed 8k RPM or torque limits

- Spindle Temperature must not exceed 70°

- If the spindle runs on high voltages, it must be ground (earthed) to the spindle and the rest of the machine (for safety, and ground faults can cause sparks that could cause premature bearing failure)

- The spindle must not be able to rotate while the drawbar is activated and vice versa

- Tools must be gently inserted into the taper to prevent damage

- Must not exceed values stated in the specification

- Spindle must not be rotated without a tool

Specifications

METRIC - Spindle

Max RPM - 8000

Max Torque - 4.5Nm Under 2500RPM, 1.5Nm Under 8000RPM

Max Power - 1.2Kw

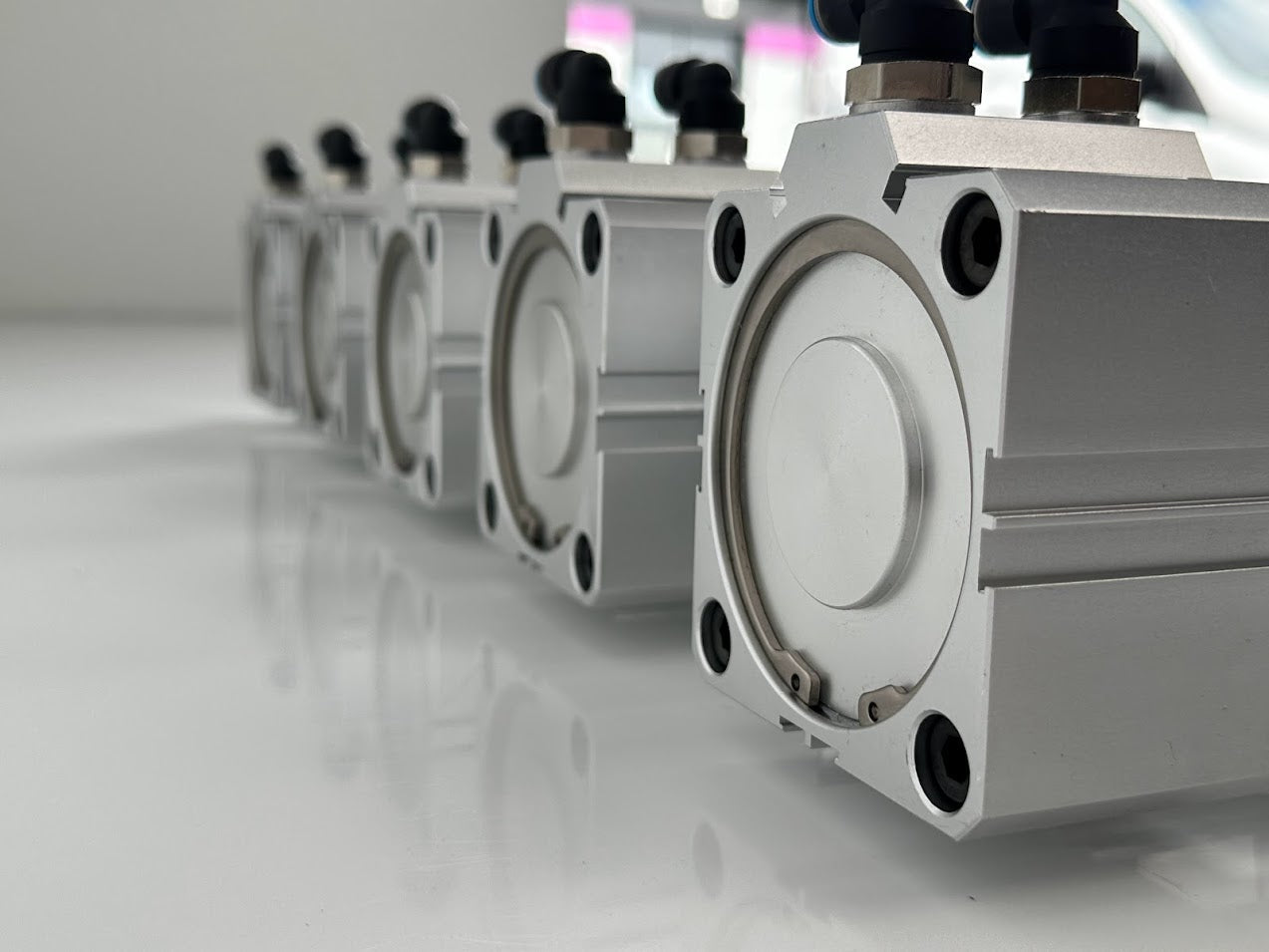

Cylinder Pressure - 6 - 8 Bar

Air Blast Max pressure - 3 Bar

Tool Clamp force - 1000N

Runout - 0.015mm at 100mm

Tramming references tolerance - +-0.01mm over 100mm

Bolt Hole spacing tolerance - +-0.02mm

Spindle weight - 8kg

Spindle material - EN3B (unhardened)

Outside dimensions - 220x130x125mm

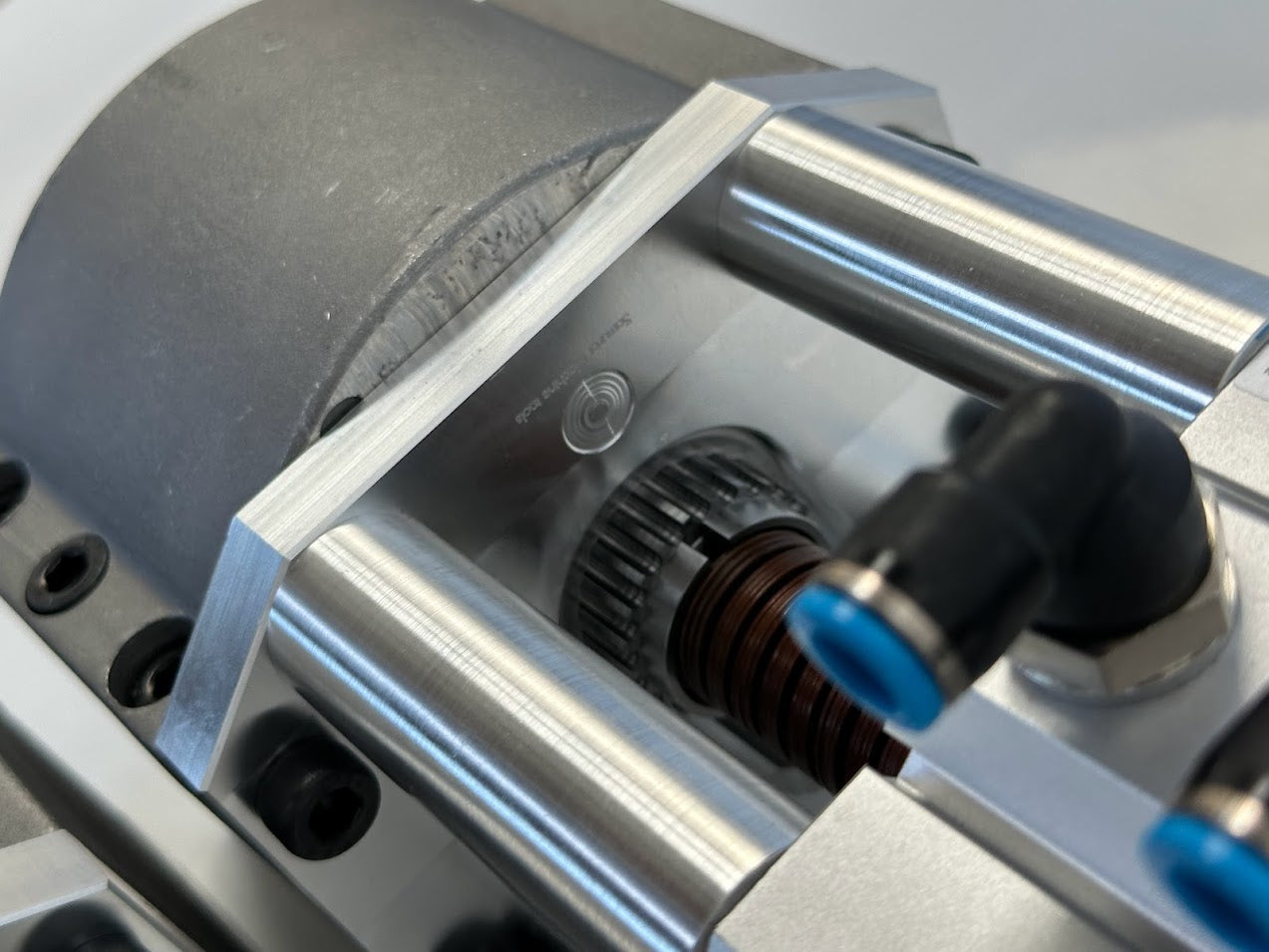

Pulley - HTD 5M 22T 10mm width

Main bearing - SKF Explorer 3208A angular contact

Lubricant - Kluber ISOFLEX NBU15

Clamp type - BT30 45° Petal Clamp

Cylinder thread - 3/8" BSP

Cylinder hose diameter - 8mm

TSA Hose diameter - 4mm

METRIC - AIRTAC Solenoid Valve

Voltage - DC24V

Type - 5 Port 2 Position

Orifice size - 12mm

Thread size - 1/8" BSPT

Pressure range - 1.5 - 8 Bar

Temperature range - 5 - 50°C

Protection - IP65

Max frequency - 5 cycles/s

Min activation time - 0.05 second

METRIC - Water filter regulator

Pump type - Single stage

Regulating pressure - 2 - 8 Bar

Thread size - 1/4" BSP

Particulate filtration - 40μm

Max flow rate - 750L / min

Size - 15.5 x 4.1cm

IMPERIAL - Spindle

Max RPM - 8000

Max Torque - 3.3ft lbf Under 2500RPM, 1.1ft lbf Under 8000RPM

Max Power - 2.1hp

Cylinder Pressure - 100 - 116 psi

Air Blast Max pressure - 43 psi

Tool Clamp force - 225lb

Runout - 0.0007" at 3.9"

Tramming references tolerance - +-0.0004" over 3.9"

Bolt Hole spacing tolerance - +-0.00078"

Spindle weight - 15.4lbs

Spindle material - EN3B (unhardened)

Outside dimensions - 8.46x5.1x4.9"

Pulley - HTD 5M 22T 0.39" width

Main bearing - SKF Explorer 3208A angular contact

Lubricant - Kluber ISOFLEX NBU15

Clamp type - BT30 45° Petal Clamp

Cylinder thread - 3/8" BSP

Hose diameter - 0.315"

IMPERIAL - AIRTAC Solenoid Valve

Voltage - DC24V

Type - 5 Port 2 Position

Orifice size - 0.47"

Thread size - 1/8" BSPT

Pressure range - 21.7 - 116 psi

Temperature range - 41 - 122°C

Protection - IP65

Max frequency - 5 cycles/s

Min activation time - 0.05 second

IMPERIAL - Water filter regulator

Pump type - Single stage

Regulating pressure - 29 - 116 psi

Thread size - 1/4" BSP

Particulate filtration - 0.00157"

Max flow rate - 26CFM

Size - 6.1 x 1.6"

This purchase grants access to Samurai M.T. Customers page

Shipping

If 'In Stock' is stated,

UK shipping in 2-3 days

Please allow up to 1 week for international delivery.

If 'Out of Stock' is stated, expected lead time 8 weeks unless otherwise stated.

Please be aware import taxes or any extra charges will have to be paid by the customer.

If there are any issues with getting the spindle delivered we are responsible unless the tracking shows that it was delivered to the correct address.

Please be aware that if the tracking shows 'Delivered' but you haven't received it, the item will be left in a safe space. You will have the option to choose delivery preferences on the DHL website.

If 2 delivery attempts fail, the items may be returned to us and you will have to pay a £100 fee to arrange re-delivery.

Returns & Cancellations

Returns of the spindle are not permitted, we will send replacement parts for any manufacturing defects.

Warranty

This product come with a 1 year manufacturers warranty against issues caused by manufacturing defects. This warranty does not cover misuse by the customer, or damage caused by exceeding the recommended RPM for normal use. We also offer free spindle taper regrinds, just send back your spindle cartridge at an agreed date and we will give you a clean taper (customer pays shipping, lead times not guaranteed).

contact@samuraimachinetools.com